About Deburring

4 types of polishing brushes that can be used with AuDeBu

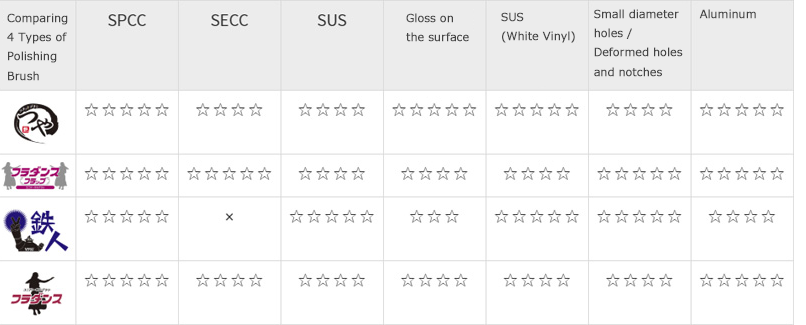

The polishing brushes that can be used with the AuDeBu series are 4 types, "Hula dance flaps / Tsuya / Tetsujin / Hula dance".

With AuDeBu series, it is possible to select and use the following four types of polishing brushes. Each has its own characteristics, and it will offer more beautiful and high quality finish by using the exact polishing brush according to the material and shape of the work,.

The polishing brushes that can be used with the AuDeBu series are 4 types, "Hula dance flaps / Tsuya / Tetsujin / Hula dance".

It is made for the image of hula dance of Hawaii and is for galvanized steel sheet. Galvanized steel sheet is iron inside, but there is zinc on top, and there is a conversion film on it. With this brush, conversion film will not be removed, but only the burrs can be chamfered. There will not see red rust even if a salt spray test is conducted as proof.

Round chamfering is available without affecting the surface of surface-treated steel sheets (SECC, SGCC, ZAM, etc.).

When deburring stainless steel products, the surface becomes shiny. named it brush"Tsuya"because gloss appeared on the surface.

Surface treatment materials (SECC, SGCC, ZAM, etc.) are hard to get scratched on the surface, and the finish is very beautiful. Fine and glossy finish. Polishin brush suitable for Round chamfering on product circumference.

It is an image from removing burr strongly. Expressing its strength, we named it "Tetsujin" .

All-round type with excellent cutting power. Products that require a strong round chamfering (applicable for equipment for manufacturing lines for medical equipment, foods that require regular cleaning, etc.) Polishing brush's shape that the tip penetrates into notches available with small diameter holes / deformed holes and notches. Stable performance can be maintained.

It is like their senior brother. It is compatible with aluminum and nonferrous metal kind of soft parts.

Beautiful finish in which the abrasive brush marks of surface-treated steel sheets (SECC, SGCC, ZAM, etc.) are inconspicuous. Polishing brush's shape will inserted into notches and that will available with small diameter holes / deformed holes and tips. Ideal for precision sheet metal.

These brushes are extremely lightweight and can be held easily with two fingers. Being light means that less load on the machine and to the gear.

Authentec believes that the best deburring machine is depend on how less weight of their brush could be.

Comparing 4 Types of Polishing Brush

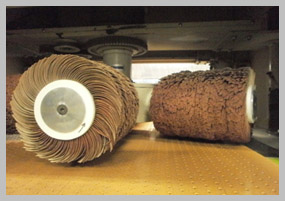

Difference of deburring effect by each brush shape

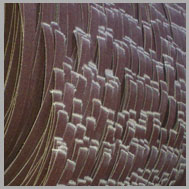

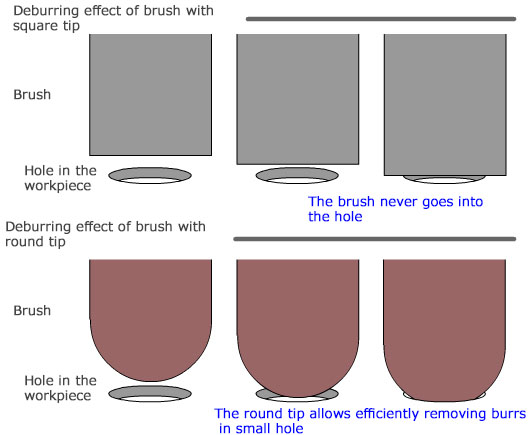

Difference by the tip shape of the brush

A brush with a round tip allows enter into the hole even if it is small. Brushes with square tips will not enter holes which is smaller than their width.

However, depending on the shape of the workpiece, it may be difficult to make a selection. Please contact us regarding brush selection.

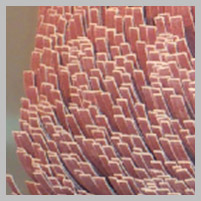

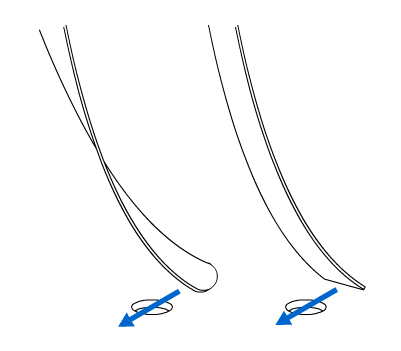

Difference of "twist" of brush

Polishing brushes have a two types, twisting brush (left) and a non-twisting brush (right). Twisted brushes are better for workpieces that change shape. For example, in case of a workpiece with many holes, it is possible to deburr the inside of the hole like "scrub".