Products

Deburring Machine:AuDeBu 1000

Feature:Deburring Machine

Round Chamfering Machine produces a surface so smooth that a nylon stocking is not snagged. AuDeBu1000 is a deburring machine specializing in round chamfering and capable of simultaneous treatment of large quantities of small-size work and medium-size work up to 1,000mm wide. Round chamfering of product edges has become the standard in sheet-metal processing. As the demand for round chamfering increases, we can meet that demand with the highest quality. We also provide a clean deburring station that is safe and comfortable.

CatalogDeburring Machine AuDeBu

We have sold 170 deburring machines manufactured by other companies to 165 businesses. Based on our customer’s requests and our maintenance experience, we have now developed our own brand, AuDeBu . Our machine’s unique anti-dust design, superior quality to minimize damage to products, user-friendly operating system, and six-brush design for high performance have all been well-received and have established our reputation for excellence among sheet-metal producing professionals throughout Japan.

Quality = Design

Remodeling machines with fundamental design problems will never make them better! You’ve seen many deburring machines that are the primary cause of dust inside factories, haven’t you? The redesigning concepts for our Sheet-Metal Deburring Machine AuDeBu were born from such lessons of the past. Seeking the ultimate deburring machine is the mission for AuDeBu through our design concept, “Simple is best.”

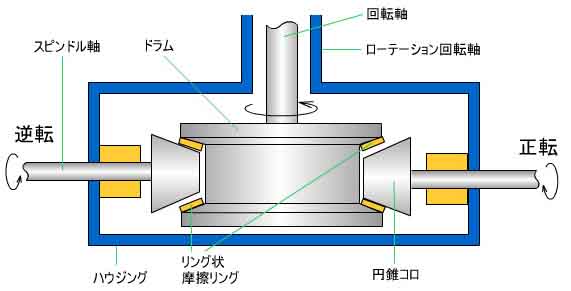

A drive system not troubled by dust!

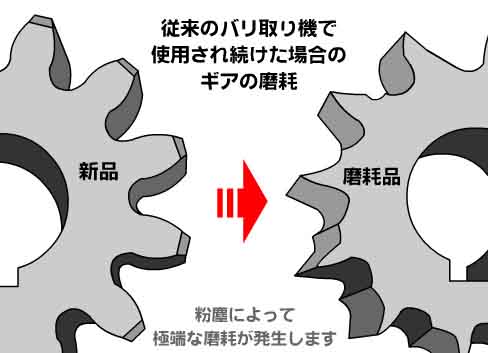

Dust created from the deburring process causes serious problems for the intricate gears of the machine, such as extreme abrasion on gears, seizing of the moving parts, and negative affects on the air pressure unit and sensor. A new configuration was adopted that solved all these problems.

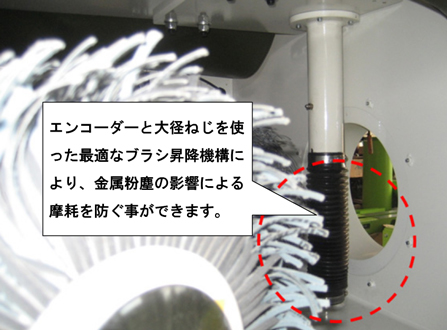

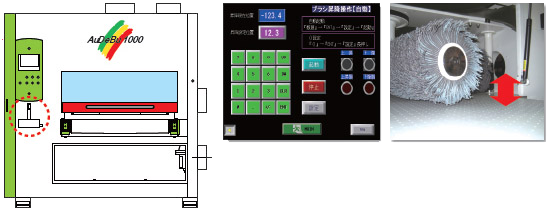

Lifting mechanism in deburring brush changed to mechanical.

The traditional vertical movement of the brush by air pressure was changed to a mechanical movement. This resulted in minimizing the influence of dust. Internal gears, air pressure equipment, or moving parts do not exist in our Sheet-Metal Deburring Machine AuDeBu! Therefore, reliability and durability have been remarkably improved!!

Efficient Six Brushes

A six-brush structure is installed in AuDeBu to increase productivity. This allows ideal deburring without excessive load pressure on the product.

Sheet-Metal Deburring Machine AuDeBu Optional Systems

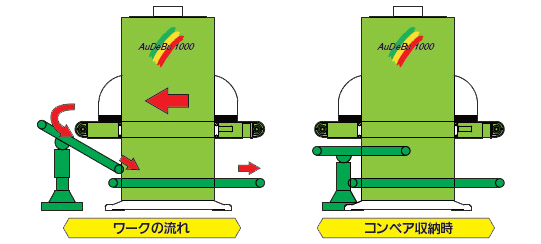

Return Conveyer System (RCS)

In the past, finished products were removed from the exit side. With our newly developed RCS (Return Conveyer System), one operator can work independently. In the new system, the conveyer runs through the interior of the machine without occupying floor space! When the conveyer is not in use, the internal space can be used as storage.

One-Touch Lock System (quick and easy brush removal)

Tighten-Free

The resin of the core wears off as it is used and the brush becomes loose on the axle causing skidding. The ORC is designed to tighten by the rotatory power of the brush and requires no manual tightening with tools.

Appendix

An additional attachment to the brush axis enables later attachment to an AuDeBu currently in use.

Bar Code Reader System (BRS)

Bar Code (CODE39) imprinted item slips and processing forms from a production management system can be used to automatically read the speed of brush revolutions, the number of rotations, the loading speed and plate thickness. Simple management with a minimum of touch panel operation!

Thickness Measurement System (TMS)

The TMS measures the thickness of the plate for round chamfering, eliminates the inputting process and prevents careless mistakes from occurring. The board thickness is measured by laser so the adjustment of the brush position is fully automatic. As a result, the development of a fully automated line is now possible.

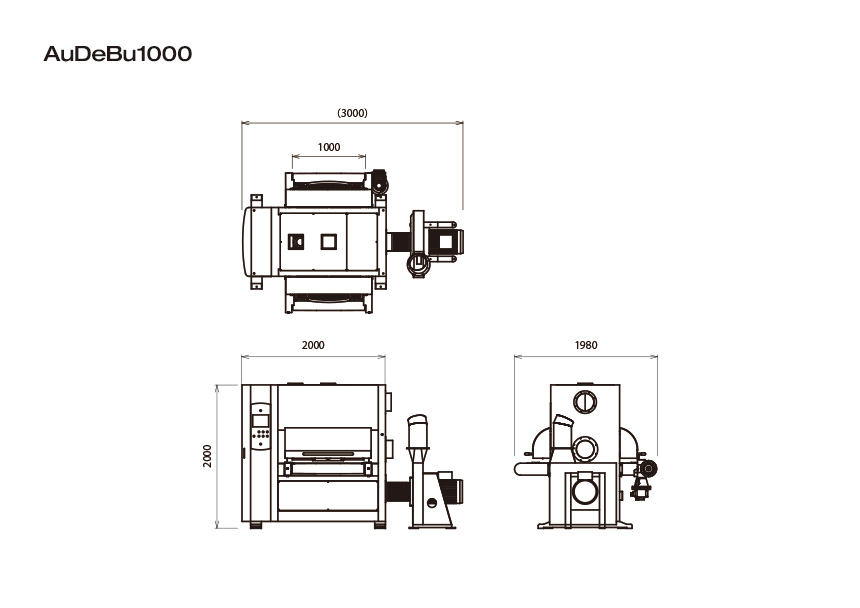

Dimensions

Technical data

| Width of the machine | 2000mm |

|---|---|

| Depth of the machine | 2110mm |

| Heights of the machine | 2000mm |

| Weight of the machine | 1500kg |

| Heights of working table | 921mm |

| Maximum height of the work | 20mm |

| Maximum width of the work/th> | 1000mm |

| Brushes | 6 |

| Brush rotation speed | 400〜1200rpm |

| Brush frame rotation speed | 5〜16rpm |

| Belt conveyor speed | 0.3〜12m/min |

| Dust suction opening | φ250mm |

| Exhaust blower opening | φ250mm |

| Main power | 21.4kW |

| Supply voltage | AC 3φ200V 50/60Hz |

※Specifications are subject to change without notice.